Anti-Reflective Coating on Glasses

Home » Anti-Reflective for Glasses Lenses

An anti-reflective treatment is an optical coating applied to ophthalmic lenses to reduce the natural reflections of the lenses, bringing not only aesthetic advantages, but mainly visual quality.

It is composed of several layers of different materials applied to the internal and external surfaces of the lenses. The number of layers is inversely proportional to the residual reflection (that almost imperceptible reflection) so that the more layers of anti-reflective treatment there is, the lower the residual reflection will be.

In addition to the anti-reflective treatment layers, at least two more important layers are normally applied: Anti-scratch, which is a resistant varnish that will make the lens resistant to scratches, and the hydrophobic layer that will reduce lens fogging.

OPTO TREATMENTS

Intensity and color of residual reflection = Lenses with less reflections

Opto Digital and Super Opto treatments incorporate 10 layers that provide an almost imperceptible residual reflection. Foto By Opto is the only anti-reflective treatment with photosensitive properties.

Only the high technology developed by Opto guarantees the adhesion of these layers to the lens and a long lifespan of the treatment. The choice of colors for the residual reflections (green, light green and light lilac) is based on providing greater comfort and protection to the user.

Lens without anti-reflective treatment

With Opto Extra-Clean, Opto Class and Opto Gold (green) anti-reflective treatment

With Super Opto anti-reflective treatment (light green)

With Opto Digital anti-reflective treatment (light purple)

Photo By Opto, the only photosensitive anti-reflective treatment

With almost imperceptible residual reflection, Opto anti-reflective treatments virtually eliminate: Indirect Reflections

These are the ones that penetrate behind the lens and reflect from the lens surfaces into your eyes. These reflections are not part of the observed image, they reduce the perception of contrast, causing the person to strain their vision more, causing great discomfort and visual fatigue.

Reflections between lens surfaces

Light rays reflect between the lens surfaces, creating ghost images and turning light sources into blur. Eliminating these reflections is particularly important and provides great comfort for the driver when driving at night.

Lens with Opto anti-reflective treatment

Lens without anti-reflective treatment

Reflections on Cornea

Light rays illuminate the cornea of the user’s eyes and reflect on the inner surface of the lens, causing discomfort when seeing one’s own eyes through the lens. This is mainly found in sunglasses, but also in glasses with high refractive index lenses materials.

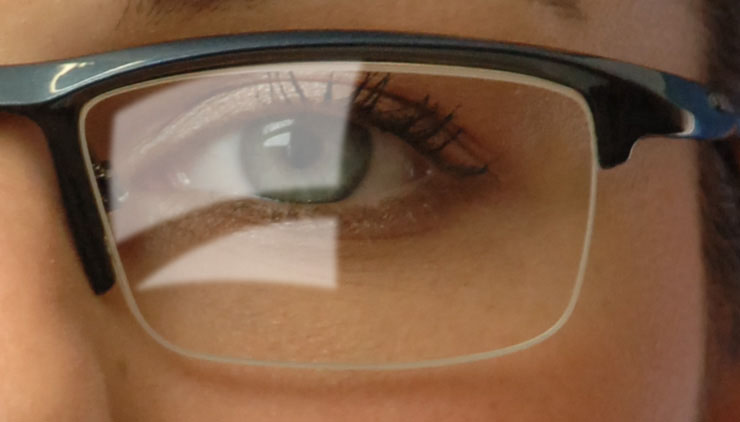

Frontal Reflexes

Light rays reflect off the outer surface of the lenses, hiding the wearer’s eyes. These reflections do not disturb the wearer of the glasses, but they do damage their image and cause great discomfort to other people who are talking to them, as the gaze is an important part of human communication.

Lens with Opto anti-reflective treatment

Lens without Opto anti-reflective treatment

MORE LAYERS = UNIFORM RESIDUAL COLOR

When optical coatings are designed (when the layers and materials are defined), it is taken into account that the light rays will be incident perpendicularly on the surface of the optical component. In the case of anti-reflective treatments, this is no different.

However, when looking at anti-reflective treatments at a non-perpendicular angle (when the lens is tilted), it is observed that the residual color varies. Sometimes this variation is significant and the treatment appears to be defective; the greater the number of layers of a treatment, the less this effect will be.

Therefore, the Super Opto and Opto Digital anti-reflective treatments, which have 10 layers, are not very susceptible to this effect. The residual color is uniform and practically does not change when the lens is tilted.

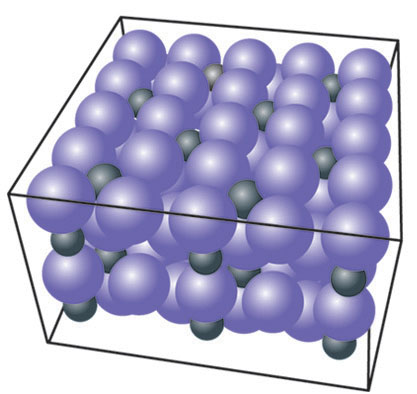

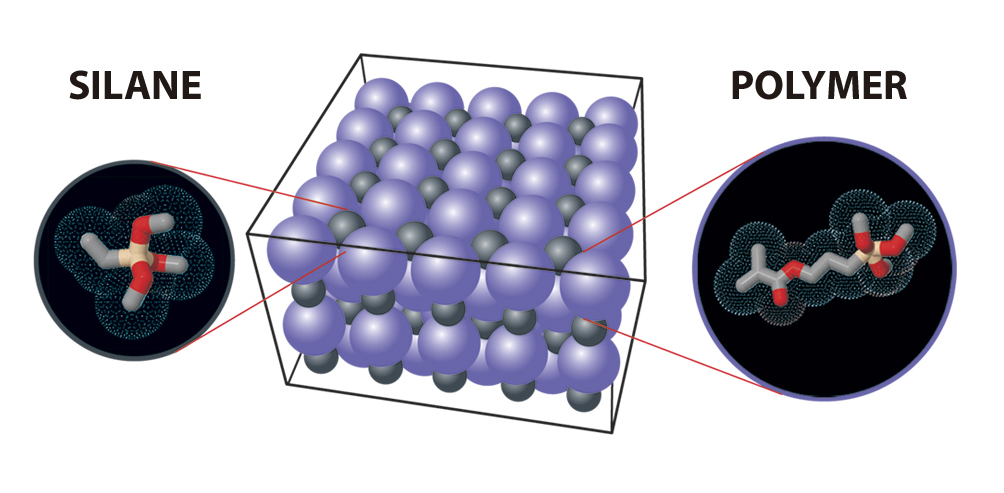

ANTI-SCRATCH COATING = MORE SCRATCH-RESISTANT LENSES

Lenses made from organic materials offer the comfort of being lightweight, but are more susceptible to scratches. Opto’s premium coatings include a high-concentration silica anti-scratch varnish base that, when applied to the lens, increases its scratch resistance by up to 10 times*.

Common low concentration varnish

Opto varnish with high concentration

(*test performed in accordance with MIL-C-00675B standard)

In addition to this advantage, the varnish polymer used by Opto is more flexible, ensuring greater resistance against cracks, which means a longer useful life, especially in thin lenses.

The lenses are subjected to a sponge and normalized pressure for 50 cycles.

The number of scratches and their depth will be proportional to the resistance of the surface.

In addition to this advantage, the varnish polymer used by Opto is more flexible, ensuring greater resistance against cracks, which means a longer useful life, especially in thin lenses.

LAYER ADHESION = NEWER LENSES FOR LONGER LIFE

Opto technology consists of the use of noble and resistant materials such as Titanium and Quartz and molecular activation through ions.

The long life of Opto coatings is achieved during the layering process when each layer is molecularly activated prior to application. This molecular activation is achieved by bombarding the lens surface, and after each layer, with ions, thus ensuring strong molecular interaction between the layers and strong adhesion (bonding) between them.

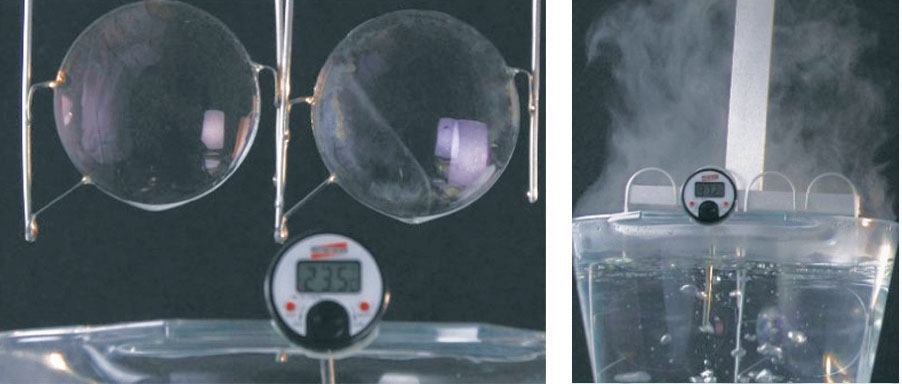

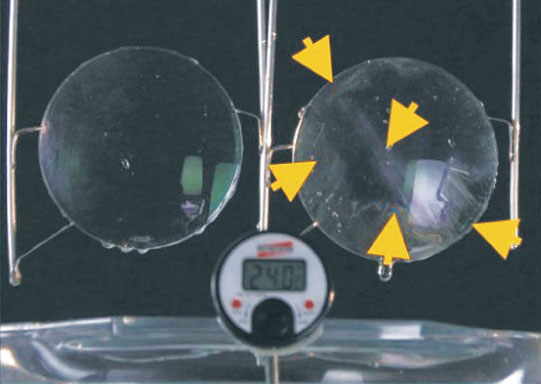

Durability tests (which check the adhesion of the anti-reflective layers) are carried out at Opto during each production cycle, thus ensuring the long life of the treatments supplied. In this test, the lenses are subjected to great stress by being immersed in boiling saline water for 2 minutes and then in water at room temperature for 1 minute. The cycle is repeated at least 6 times and the treatment must not show any deterioration (peeling off).

Comparative tests, as shown in the figures, prove that Opto treatments are extremely resistant and long-lasting.

Opto Anti-Reflective and common AR are subjected to temperature variation cycles (cold and hot).

At the end of the test, the Opto Anti-Reflective remains intact, while the common AR flakes off.

THIS MEANS THAT OPTO'S ANTI-REFLECTIVE TREATMENTS HAVE GREATER DURABILITY AGAINST PEELING.

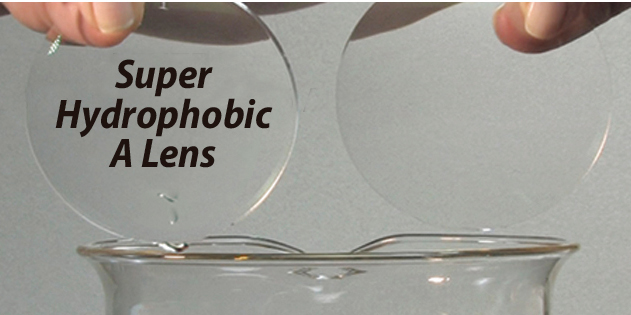

OLEO-HYDROPHOBIC COATING = EASIER TO CLEAN LENSES

Lenses with anti-reflective coatings are often known for being difficult to clean. Opto’s Anti-Reflective coatings include a state-of-the-art Oil-Hydrophobic outer layer that makes cleaning quick and easy. Opto’s Oil-Hydrophobic outer layer has a superhydrophobic contact angle of 120 degrees.

It is so efficient that not even overhead projector pens (the culprits of lens smudges) can stick to the lens surface. Opto’s Oil-Hydrophobic layer also prevents lenses from fogging up easily.

EFFICIENT AND DURABLE

Furthermore, resistance tests of Opto anti-reflective treatments show that Opto’s Oil-Hydrophobic layer has enormous durability. The test to demonstrate this durability consists of rubbing a microfiber cloth on the same region of a lens thousands of times, demonstrating the high resistance and long lifespan of the Oil-Hydrophobic layer.

Comparative tests have shown that Opto’s Oil-Hydrophobic layer has the longest lifespan of any similar layer on the market.

The lenses are subjected to thousands of cleanings with the microfiber, always in the same area.

The pressure exerted simulates a person cleaning the lens with their hands.

The comparative test of the durability of the Oil-Hydrophobic layer is done by immersing the lenses in a container with oil.

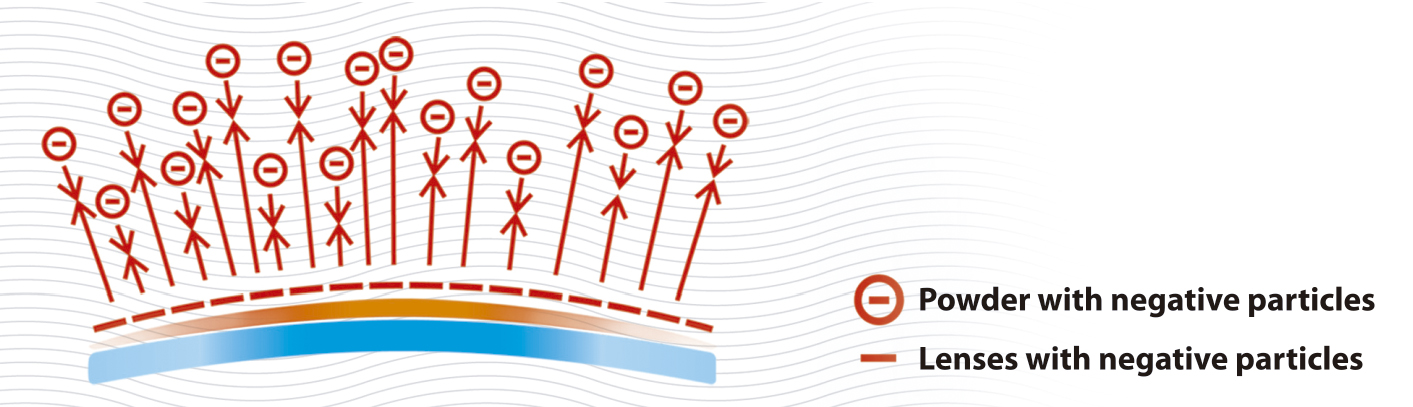

ANTI-STATIC COATING = LENSES ARE HARDER TO GET DIRTY

Opto was the first company in Brazil to produce an anti-reflective treatment with an anti-static layer.

The anti-static layer of Opto treatments neutralizes the electrical charges created when cleaning the lenses (static electricity), preventing dust particles from being attracted to the surface and keeping the lens cleaner for longer.

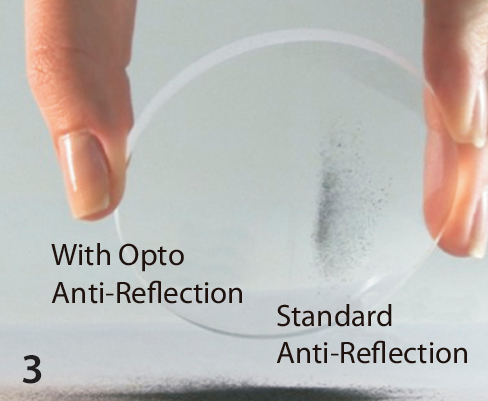

A simple test has shown that lenses with Opto treatments get up to 8 times less dirty than lenses without the anti-static layer. Two lenses, one with a standard anti-reflective coating and the other with Opto anti-reflective coating, were properly cleaned and left in any environment. After 1 hour, they were placed under a projector with Xenon light and it was possible to see and demonstrate how much the Opto anti-static coating keeps the lens clean for longer.

UV PROTECTION = TREATMENTS THAT PROTECT AGAINST ULTRAVIOLET RAYS

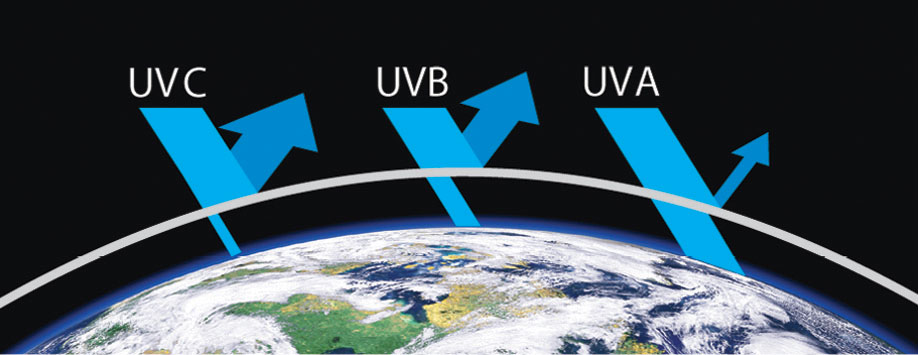

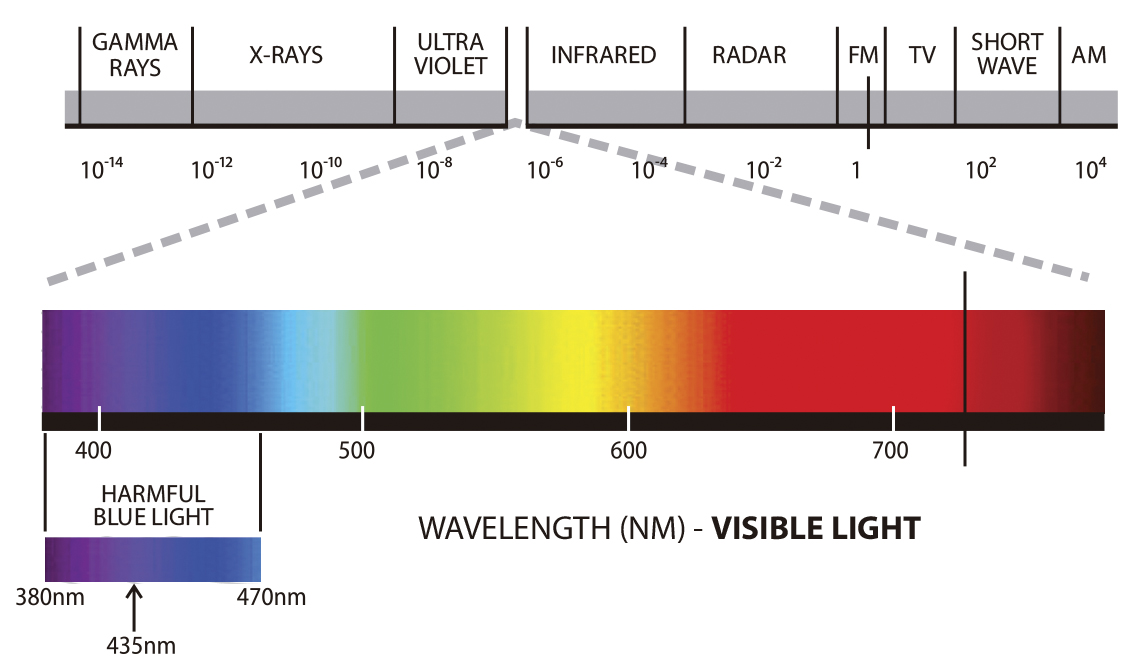

Ultraviolet rays are part of the spectrum of electromagnetic radiation present in nature. They are divided into UVA, UVB and UVC according to their penetration into the atmosphere and the damage they can cause to biological cells. UVA rays, together with part of the UVB transmitted by the damaged ozone layer, form the well-known Ultraviolet Radiation (UVR), which is harmful to human health and in particles to the eyes, and can cause various eye diseases.

– UVC rays are practically all absorbed by the Earth’s atmosphere and the small amount that reaches the surface does not affect human health.

– UVB rays are well absorbed (almost 90%) by the ozone layer, but as the ozone layer is thin in many parts of the globe, they reach the Earth’s surface with the potential to cause skin and eye diseases.

– UVA rays pass through the atmosphere and reach the Earth’s surface with the potential to cause harm to health.

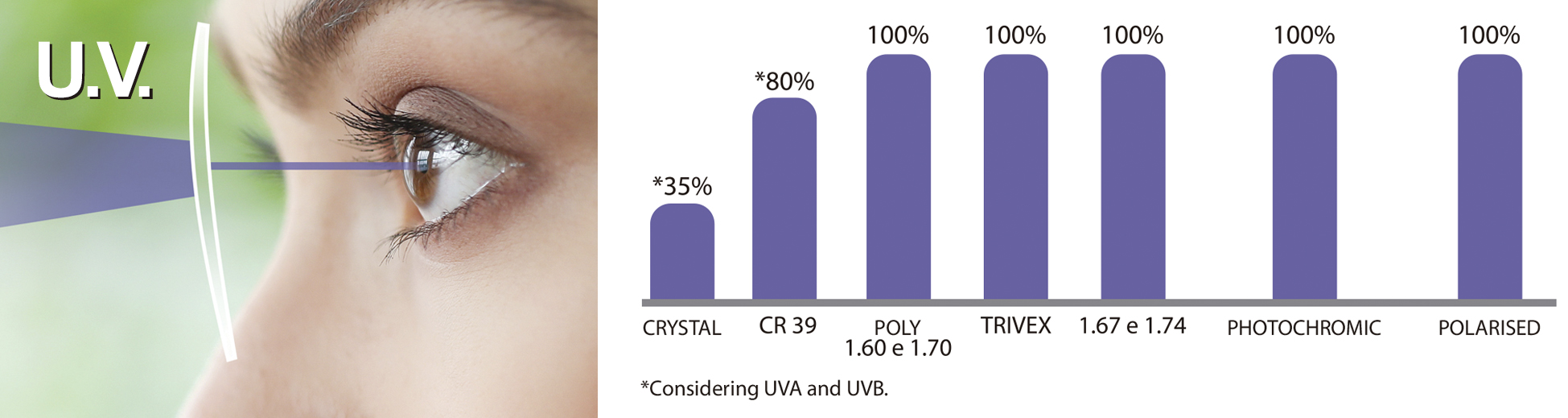

Lens materials are capable of absorbing almost all UV rays. They are 100% absorbed by polycarbonate and high-index lenses, and more than 90% by lenses made of standard materials.

PERCENTAGE OF UV RADIATION ABSORBED BY EACH TYPE OF MATERIAL

PERCENTAGE OF UV RADIATION FOR EACH TYPE OF ANTI-REFLECTIVE TREATMENT

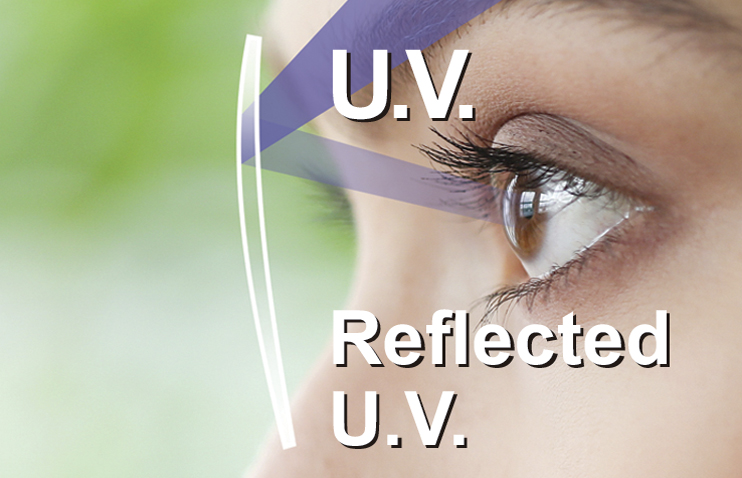

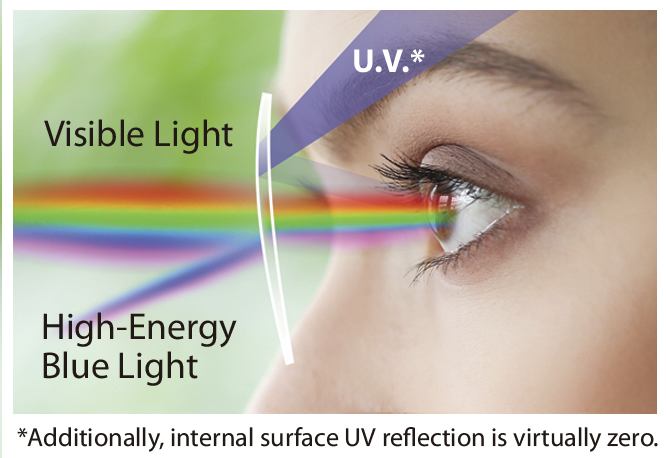

Common anti-reflective coatings reflect UV rays in large percentages. When applied to the outer layer of lenses, they actually provide protection by reflecting UV rays. However, as shown in the figure, when applied to the inner surface of lenses, these coatings work against protection by reflecting UV rays back into the wearer’s eyes.

Opto has developed a technology for its anti-reflective treatments capable of reducing the reflection of Ultra Violet light from the inner surface of the lenses. The treatment applied to the outer surface of the lens remains the same, reflecting UV and thus providing double protection.

The drawings below show the percentages of Ultra Violet light to which the eyes of a user wearing glasses may be exposed when using a lens without anti-reflective treatment, with common treatment and with Opto UV treatments.

Many studies show that the light emitted by computer monitors, cell phone screens and tablets causes visual fatigue, discomfort and can even affect sleep. Other clinical studies show that violet light can be harmful to the eyes and contributes to the development of eye diseases.

To protect your eyes from the wear and tear of modern life, Opto has developed the Opto Digital treatment.

Opto Digital reduces the amount of harmful light reaching the eyes. It does this selectively by protecting the eyes from the most harmful wavelengths and improving visual acuity. Blue light tends to scatter easily, reducing image sharpness and color contrast. By eliminating this portion of the scattered blue light, Opto Digital improves visual acuity.

*Additionally, the reflection of Ultra Violet on the internal surface is practically zero.

BENEFITS OF OPTO DIGITAL TREATMENT

Reduces visual fatigue and symptoms such as interference in the biological cycle associated with computer, cell phone and tablet screens.

Blocks only the percentage needed to protect against EXCESS high-energy blue light.

By reflecting excess high-energy blue light, it prevents damage to the retina caused by excess blue light.

Almost completely eliminates UV rays reflected on the inner surface of the lens.

It is a premium anti-reflective coating from Opto with a highly resistant anti-scratch layer, high layer adhesion and great durability, anti-aesthetic layer and latest generation oleo-hydrophobic layer.

The Evolution in Anti-Reflection Coatings

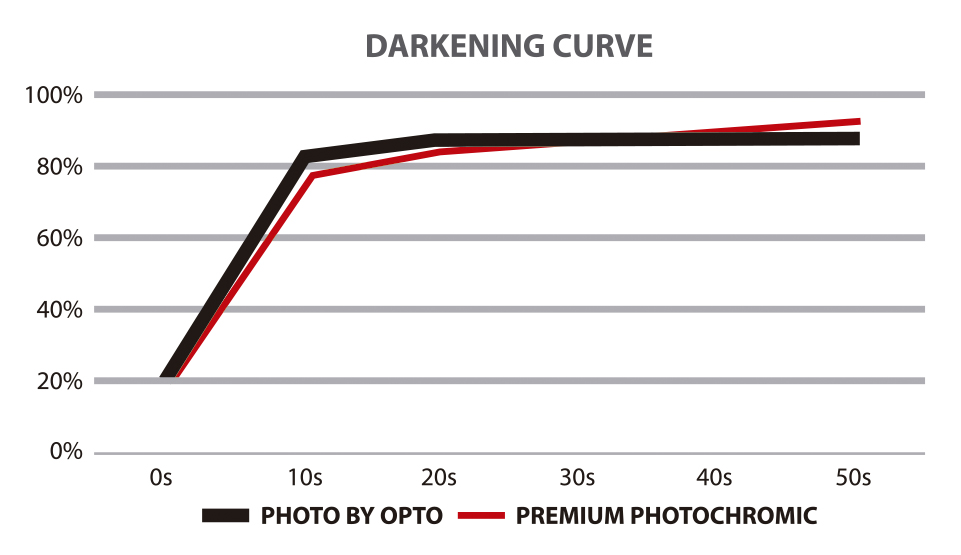

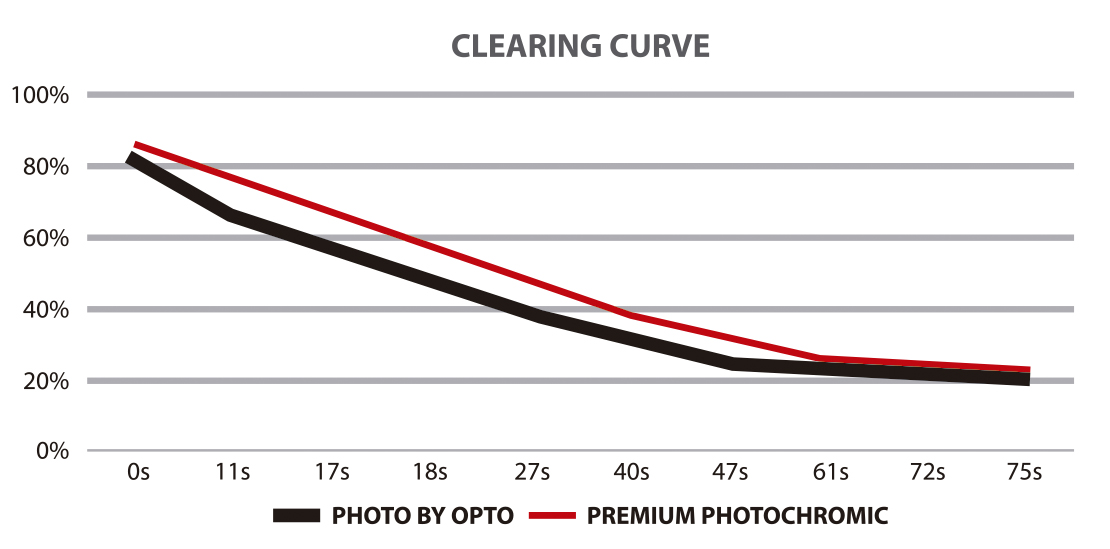

The Anti-reflective Photo By Opto treatment is yet another innovation introduced by Opto.

Foto By Opto is an anti-reflective treatment with all the characteristics of the most modern treatments, but photosensitive.

Foto By Opto was developed to provide the highest performance of two technologies: anti-reflective and photosensitive in a single treatment.

Lenses made of any material can receive the new Foto By Opto, bringing countless advantages to laboratories, opticians and especially to users.

O Foto By Opto:

- Dims faster (reaches 80% dimming in 10 seconds)

- Clears faster (returns to original transparency in less than 1 minute)

- Protects against direct UV rays (fully absorbs UV rays when activated)

- Protects against indirect UV rays (internal anti-reflective treatment that reflects less than 2% of UV)

- Greater durability (greater adhesion of layers)

- Scratch resistant (high density anti-scratch layer)

- Harder to get dirty (anti-aesthetic layer that prevents the attraction of airborne particles)

- Easier to clean (superhydro-oleophobic layer that makes cleaning easier)